In the rapidly evolving landscape of construction, ensuring the safety of workers while maintaining efficient operations is paramount. Leveraging AI and robotics, innovative solutions are now emerging to address these critical aspects. This blog explores how advanced AI systems are revolutionizing construction site safety.

Introduction

Construction sites are inherently hazardous environments, requiring numerous safety protocols to protect workers. However, monitoring and enforcing these protocols can be challenging due to the dynamic and often chaotic nature of construction activities. AI-powered solutions offer a new way to enhance safety by automatically detecting safety compliance. This blog delves into an AI-based system designed to ensure safety on construction sites, highlighting its features, usage, and performance.

Usage

The AI system is designed to enhance construction site safety through several key functionalities:

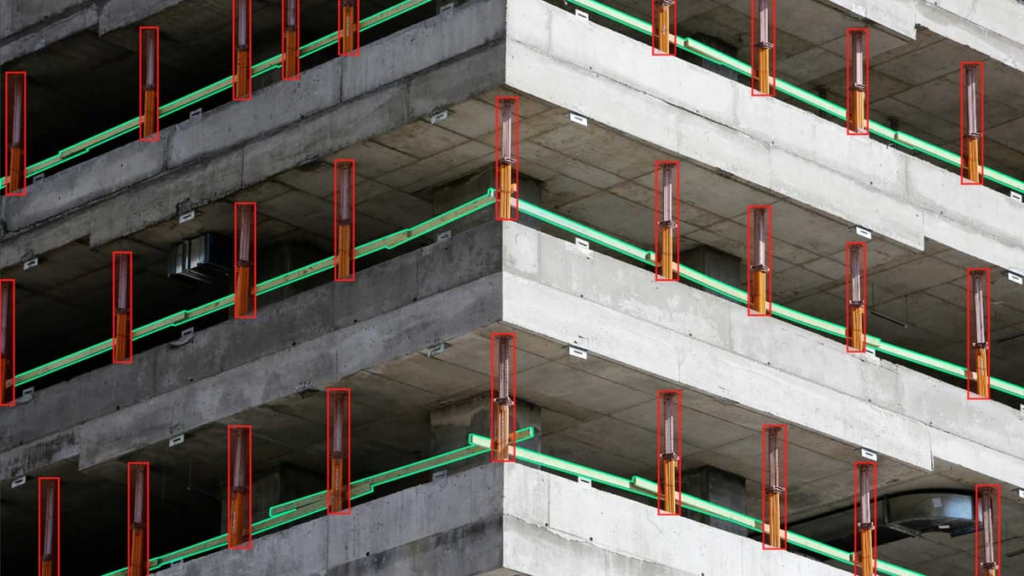

- Safety Monitoring: The system continuously monitors workers to ensure they are wearing safety hats, vests, and masks. Cameras placed strategically around the construction site capture live video feeds, which are then processed in real-time by the AI system. If a worker is found not complying with these safety protocols, the system immediately records a video of the breach. This video continues to be recorded until the individual leaves the camera frame, ensuring a comprehensive record of the non-compliance incident. Each recorded video is timestamped, providing precise information about when and where the safety breach occurred. This feature ensures that every instance of non-compliance is documented, allowing for thorough review and analysis.

- Incident Reporting: Once a safety breach is detected, the system promptly informs the site manager. The alert includes the exact time and location of the incident, along with the recorded video footage. This allows the site manager to take quick and appropriate action, such as addressing the non-compliant worker or reviewing the incident with the team to prevent future occurrences. The ability to receive real-time notifications ensures that safety issues are addressed promptly, minimizing the risk of accidents and injuries.

- Proactive Safety Management: Beyond monitoring and incident reporting, the system also contributes to proactive safety management. By continuously analyzing video feeds, the AI can identify patterns and trends in safety compliance. For example, if non-compliance incidents are more frequent at certain times of the day or in specific areas of the site, the system can highlight these trends. This information allows site managers to take preventive measures, such as increasing supervision during high-risk periods or conducting targeted safety training for workers.

Dataset and Model

To develop and train this AI system, a comprehensive dataset is utilized, focusing on construction site safety. The dataset includes images and videos of workers with and without safety gear. The key components of the dataset and model include:

- Pretrained Model: The AI model is built upon the YOLOv8n pretrained model, known for its high accuracy and speed in object detection tasks.

- Dataset Source: The dataset used for training is sourced from Roboflow, a platform that provides tools for managing and annotating datasets.

- Categories: The dataset is categorized into different safety gear types, such as Hardhat, Safety Vest, and Mask. It also includes categories for non-compliance, like No-Safety Vest, No-Mask, and No-Helmet.

- Project Details: The dataset is hosted on Roboflow under the project “construction-site-safety”.

- Data Distribution: The dataset is divided into training, validation, and test sets. The training set is used to train the AI model, the validation set is used to fine-tune the model’s parameters, and the test set is used to evaluate the model’s performance. This distribution ensures that the model is robust and can generalize well to new data.

- Custom Training: The model is trained on Google Colab, utilizing a powerful A100 GPU to handle the computational demands. This setup allows for efficient training and fine-tuning of the model to achieve high accuracy in detecting safety gear and identifying non-compliance.

Performance Analysis

The AI system’s performance is enhanced by several key features:

- Pre-installed Software: The system runs on a platform equipped with Ubuntu 22.04, ROS2, OpenCV, and CUDA. These software tools provide a robust foundation for developing and deploying AI and robotics applications. ROS2 (Robot Operating System) facilitates communication between different components of the system, while OpenCV and CUDA enable efficient image processing and deep learning operations.

- Powerful GPU: The system is equipped with a powerful GPU, which is essential for handling the computational demands of real-time video processing. The GPU accelerates the training and inference of deep learning models, ensuring that the system can process high-resolution video feeds at high frame rates.

- High-Resolution Camera: The system uses a 1920×1080 camera capable of capturing up to 23 frames per second. This high-resolution camera provides clear and detailed images, which are crucial for accurately detecting safety gear. The high frame rate ensures that the system can monitor the site continuously without missing any important events.

These features enable the system to achieve remarkable benchmarks, including high accuracy in detecting safety gear, as well as efficient real-time processing. The combination of advanced hardware and software ensures that the system can operate reliably in the demanding environment of a construction site.

Graphical Analysis

A crucial aspect of the system is its ability to analyze and report trends in safety compliance over time. For instance, a graph can be shown where it compares the number of violations versus the time of day. This helps in identifying peak times of non-compliance, allowing for targeted interventions. The graph is generated by aggregating data from the recorded incidents, providing a visual representation of safety trends.

During peak times of non-compliance, the system can send higher numbers of immediate alerts to the manager or the concerned person. This ensures that safety breaches are addressed promptly, even during busy periods. By providing real-time insights and notifications, the system helps site managers maintain a high level of safety at all times.

Conclusion

Incorporating AI into construction site operations significantly enhances safety. The system described here not only ensures compliance with safety protocols by recording and timestamping breaches but also provides a comprehensive solution for modern construction sites. The ability to monitor safety in real-time, report incidents promptly, and analyze trends over time makes this AI system a powerful tool for improving safety on construction sites.

By leveraging AI and robotics, we can create a safer work environment for construction workers, ultimately leading to more productive and secure construction sites. Additionally, the system runs on a server, ensuring continuous and reliable monitoring without interrupting site operations. The server-based architecture allows the system to scale easily, supporting multiple cameras and large construction sites.

The system also integrates GPS data to pinpoint the exact location of each safety violation, providing even more detailed information for site managers. This level of detail ensures that every incident is documented accurately, enabling better oversight and management of safety protocols.

The future of construction looks safer and more efficient with AI-powered safety systems. As technology continues to advance, we can expect even more innovative solutions to emerge, further enhancing the safety and efficiency of construction operations. By embracing AI and robotics, the construction industry can achieve new levels of safety, productivity, and overall performance, paving the way for a brighter and safer future.