In the world of construction, resource management and operational efficiency are paramount. With construction sites bustling with activities and materials moving constantly, keeping track of these resources manually can be a daunting task. To address this challenge, advanced AI-powered solutions are revolutionizing construction operations, offering unparalleled accuracy and efficiency.

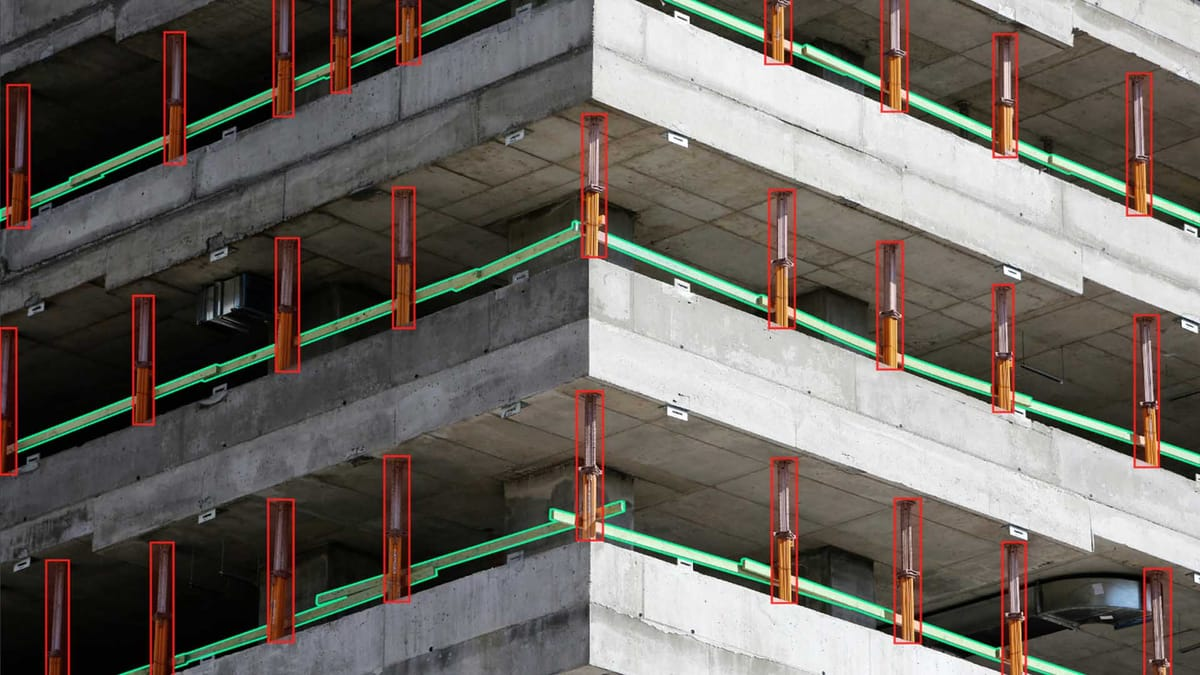

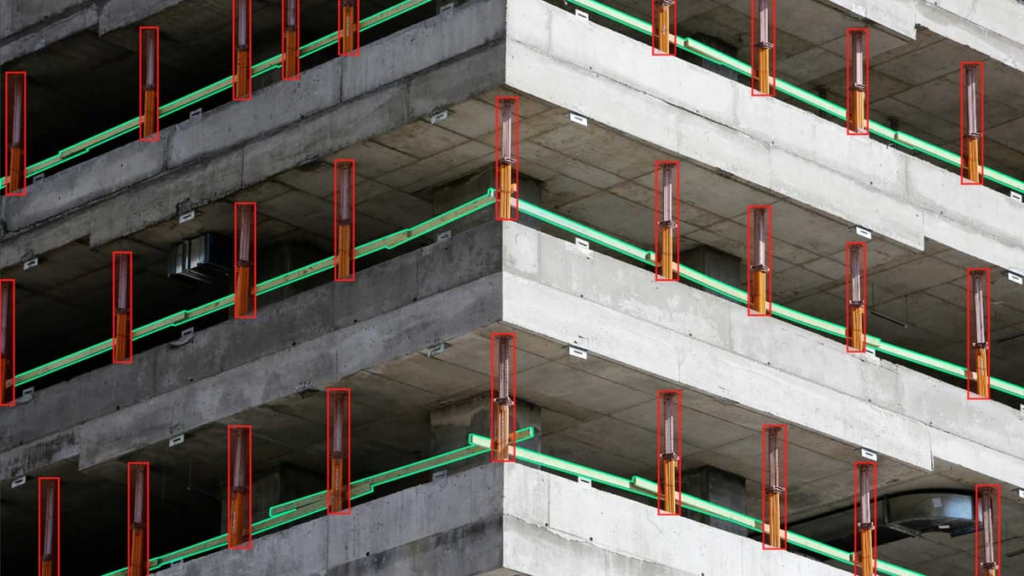

This blog dives deep into a cutting-edge AI model designed to monitor and track materials handled by robot dumpers on construction sites. Utilizing YOLOv8 for object detection and tracking, the model automates the process of resource tracking, ensuring precise and real-time insights for site managers and stakeholders.

Introduction

Construction sites are dynamic environments with numerous moving parts. From materials being delivered to tools being transported, keeping track of every item is crucial to ensure smooth operations and prevent resource wastage. Traditionally, manual methods of tracking were prone to errors and inefficiencies.

This innovative AI model provides a robust solution, leveraging state-of-the-art object detection and tracking algorithms to automate the process. By focusing on robot dumpers, a key element in material transport, the model ensures that every item is accounted for with unparalleled precision.

Objectives and Capabilities

1. Material Flow Automation

The model automates the tracking of materials moving into and out of robot dumpers, reducing human intervention and errors.

2. Advanced Object Detection

Powered by YOLOv8, a highly accurate and efficient object detection model, it identifies and tracks materials such as cement blocks, bricks, and cement bags.

3. ROI-Based Monitoring

By defining a Region of Interest (ROI) around the dumper, the model ensures focused detection, ignoring irrelevant background activities on the construction site.

4. Bidirectional Tracking

The model tracks materials moving in both directions:

- Into the dumper: Logs items being loaded.

- Out of the dumper: Tracks items being unloaded.

5. Daily Summarized Reports

At the end of each day, the system generates detailed reports, including:

- The types of materials handled.

- A count of each material moved.

- Timestamped records of all detections.

6. Real-Time Alerts

The system can notify managers in real time if any discrepancies or unusual activities are detected, ensuring immediate intervention.

7. Scalability and Integration

Designed for flexibility, the model can be scaled to monitor multiple dumpers across large construction sites and integrate seamlessly with existing site management systems.

How It Works

1. Setting Up the ROI

Before the system begins operation, users define an ROI around the dumper. This area is where all detections and tracking occur, ensuring focused and efficient monitoring.

2. Real-Time Object Detection and Tracking

Using YOLOv8, the system processes live video feeds from high-resolution cameras mounted around the dumper. The model detects objects within the ROI, classifying them into predefined categories such as bricks, cement blocks, and bags.

3. Bidirectional Material Flow Tracking

The model tracks the movement of objects in and out of the ROI, distinguishing between items being loaded onto the dumper and those being offloaded. This ensures a comprehensive record of all material flows.

4. Data Logging and Aggregation

Every detection and movement is logged with detailed information:

- Type of object

- Direction of movement (into or out of the dumper)

- Timestamps

- Unique object IDs for tracking individual items

5. Report Generation

At the end of each day, the system compiles all logged data into a detailed report. This report includes:

- Total count of each material handled

- Trends in material movement (e.g., peak times of activity)

- Anomalies or discrepancies observed

Model Training and Development

1. Training Process

The model was trained on Google Colab, utilizing its A100 GPU for efficient computation. A pre-trained YOLOv8 model served as the foundation, fine-tuned with construction-specific data.

2. Dataset Details

A robust dataset was curated from various construction scenarios, featuring images and videos of materials like bricks, cement blocks, and bags.

- Categories: Cement blocks, Bricks, Cement Bags, etc.

- Data Source: Custom dataset annotated with tools like Roboflow for high accuracy.

- Distribution: Split into training (70%), validation (20%), and testing (10%) sets for optimal performance.

3. Fine-Tuning for Specific Use Cases

The model was fine-tuned to detect and track objects within the unique conditions of construction sites, such as poor lighting, cluttered backgrounds, and varying object orientations.

Hardware and Software Features

1. High-Resolution Cameras

The system uses 1080p cameras capable of capturing 23 frames per second, ensuring clarity and accuracy in object detection and tracking.

2. GPU Acceleration

Equipped with NVIDIA GPUs, the system processes high-resolution video feeds in real time, maintaining low latency and high performance.

3. Software Stack

- Ubuntu 22.04: For robust and reliable system operations.

- YOLOv8: For state-of-the-art object detection.

- OpenCV: For efficient video processing.

- CUDA: To leverage GPU acceleration.

Use Cases and Benefits

- Enhanced Resource Management :- Automating the tracking of materials minimizes waste and ensures efficient utilization of resources.

- Improved Transparency :- Detailed logs and reports provide a clear record of material movement, enabling accountability and transparency.

- Time and Cost Savings :- By automating a time-consuming manual process, the system saves valuable time and reduces operational costs.

- Scalability :- The model can easily be scaled to monitor multiple dumpers or other material handling systems, making it suitable for large-scale construction sites.

- Real-Time Oversight :- Managers can access real-time data and reports, allowing them to make informed decisions promptly.

Future Enhancements

- Integration with IoT Sensors : – Combining the model with IoT sensors could provide additional data points, such as weight and volume of materials handled.

- Predictive Analytics :- Analyzing historical data to predict material needs, optimizing inventory and transport schedules.

- Enhanced Detection in Harsh Conditions :- Adapting the model for environments with poor visibility, such as dust or rain.

- Multi-Site Integration :- Expanding the system to manage and report on multiple sites from a centralized dashboard.

Conclusion

This YOLOv8-based object detection and tracking model is a game-changer for construction sites. By automating material tracking, generating detailed reports, and providing real-time insights, it ensures higher efficiency, transparency, and resource optimization.

As AI and robotics continue to advance, solutions like this are setting new standards in the construction industry, paving the way for smarter, safer, and more productive operations. With features like ROI-based monitoring, daily reports, and bidirectional tracking, this model is a vital tool for modern construction site management.

Embracing such technologies will not only enhance operational efficiency but also empower site managers and stakeholders to make informed decisions, ensuring that every resource is used effectively and every material is accounted for. The future of construction is here—and it’s powered by AI.